Gradient-Based Dovetail Joint Shape Optimization for Stiffness

Proc. ACM Symposium on Computational Fabrication, October 2023

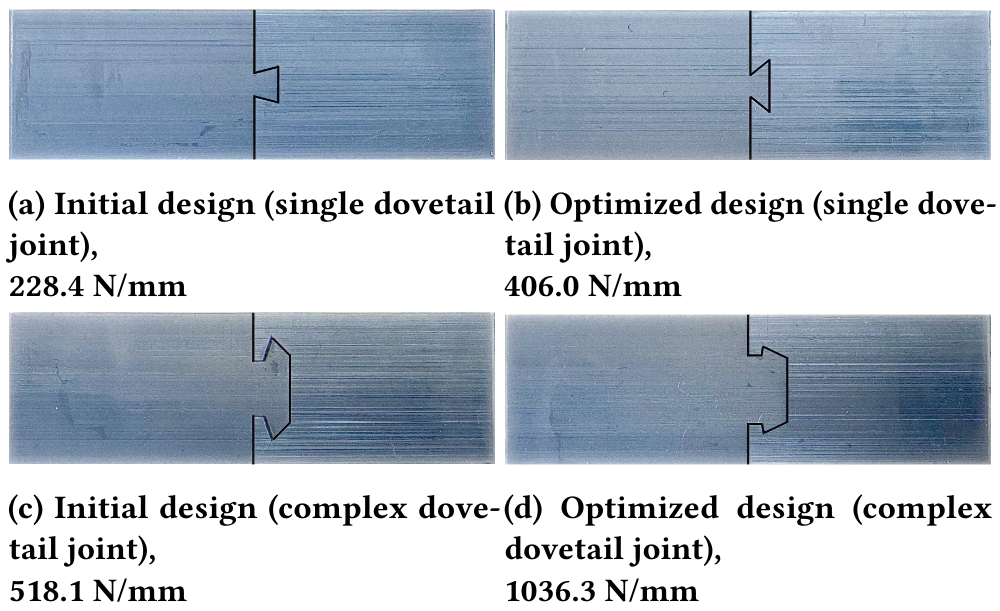

Initial and optimized designs of single and complex

dovetail joints with average stiffness measured over three

batches and external forces applied on the two sides. (a) (c):

initial (randomly chosen) single and complex dovetail joints.

(b) (d): optimized single and complex dovetail joints, which

provide greater stiffness.

Abstract

It is common to manufacture an object by decomposing it into

parts that can be assembled. This decomposition is often required

by size limits of the machine, the complex structure of the shape,

etc. To make it possible to easily assemble the final object, it is

often desirable to design geometry that enables robust connections

between the subcomponents. In this project, we study the task of

dovetail-joint shape optimization for stiffness using gradient-based

optimization. This optimization requires a differentiable simulator

that is capable of modeling the contact between the two parts of a

joint, making it possible to reason about the gradient of the stiffness

with respect to shape parameters. Our simulation approach uses a

penalty method that alternates between optimizing each side of the

joint, using the adjoint method to compute gradients. We test our

method by optimizing the joint shapes in three different joint shape

spaces, and evaluate optimized joint shapes in both simulation and

real-world tests. The experiments show that optimized joint shapes

achieve higher stiffness, both synthetically and in real-world tests.

Paper

LInks

- This publication on arXiv

Citation

Xingyuan Sun, Chenyue Cai, Ryan P. Adams, and Szymon Rusinkiewicz.

"Gradient-Based Dovetail Joint Shape Optimization for Stiffness."

Proc. ACM Symposium on Computational Fabrication, October 2023.

BibTeX

@inproceedings{Sun:2023:GDJ,

author = "Xingyuan Sun and Chenyue Cai and Ryan P. Adams and Szymon Rusinkiewicz",

title = "Gradient-Based Dovetail Joint Shape Optimization for Stiffness",

booktitle = "Proc. ACM Symposium on Computational Fabrication",

year = "2023",

month = oct

}