More Stiffness with Less Fiber: End-to-End Fiber Path Optimization for 3D-Printed Composites

Proc. ACM Symposium on Computational Fabrication, October 2023

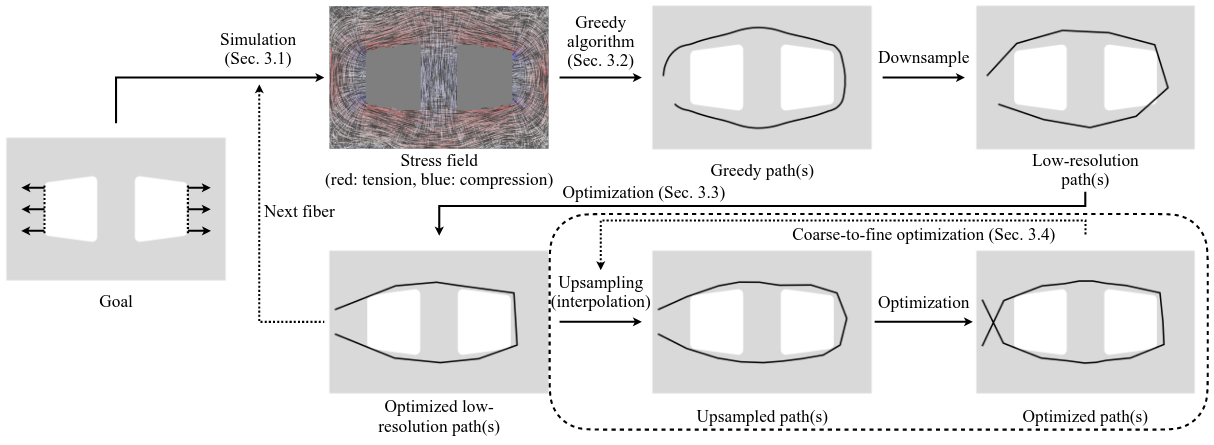

We repeatedly use the finite element method to calculate the stress field of the object, extract a new fiber path

by greedily “walking” on the stress field, optimize the downsampled fiber path with an objective function designed to

maximize stiffness and regularize fiber paths to be manufacturable, and finally upsample and optimize all the fiber paths

several times to perform coarse-to-fine optimization.

Abstract

In 3D printing, stiff fibers (e.g., carbon fiber) can reinforce thermoplastic polymers with limited stiffness. However, existing commercial digital manufacturing software only provides a few simple fiber

layout algorithms, which solely use the geometry of the shape. In

this work, we build an automated fiber path planning algorithm

that maximizes the stiffness of a 3D print given specified external

loads. We formalize this as an optimization problem: an objective

function is designed to measure the stiffness of the object while

regularizing certain properties of fiber paths (e.g., smoothness). To

initialize each fiber path, we use finite element analysis to calculate

the stress field on the object and greedily “walk” in the direction

of the stress field. We then apply a gradient-based optimization

algorithm that uses the adjoint method to calculate the gradient of

stiffness with respect to fiber layout. We compare our approach, in

both simulation and real-world experiments, to three baselines: (1)

concentric fiber rings generated by Eiger, a leading digital manufacturing software package developed by Markforged, (2) greedy

extraction on the simulated stress field (i.e., our method without

optimization), and (3) the greedy algorithm on a fiber orientation

field calculated by smoothing the simulated stress fields. The results show that objects with fiber paths generated by our algorithm

achieve greater stiffness while using less fiber than the baselines—

our algorithm improves the Pareto frontier of object stiffness as

a function of fiber usage. Ablation studies show that the smoothing regularizer is needed for feasible fiber paths and stability of

optimization, and multi-resolution optimization helps reduce the

running time compared to single-resolution optimization

Paper

Links

- This publication on arXiv

Citation

Xingyuan Sun, Geoffrey Roeder, Tianju Xue, Ryan P. Adams, and Szymon Rusinkiewicz.

"More Stiffness with Less Fiber: End-to-End Fiber Path Optimization for 3D-Printed Composites."

Proc. ACM Symposium on Computational Fabrication, October 2023.

BibTeX

@inproceedings{Sun:2023:MSW,

author = "Xingyuan Sun and Geoffrey Roeder and Tianju Xue and Ryan P. Adams and

Szymon Rusinkiewicz",

title = "More Stiffness with Less Fiber: End-to-End Fiber Path Optimization for

{3D}-Printed Composites",

booktitle = "Proc. ACM Symposium on Computational Fabrication",

year = "2023",

month = oct

}